-

OpEx-5SVC-5S and Visual Controls

Channel: OpEx Academy NZThe source, titled “5S & Visual Controls for High Performance Workplace” by Vishnu Rayapeddi, outlines a comprehensive workshop focused on implementing the 5S methodology within an operational setting. This approach, originating from lean manufacturing principles, aims to create a safe, clean, and organised workplace to improve efficiency and quality. The document details each of the five “S” steps: Sort, Set-in-Order, Shine, Standardise, and Sustain, providing practical guidance, self-assessment tools, and examples for implementation. Ultimately, the objective is to achieve “World-Class Manufacturing” through disciplined workplace organisation and the effective use of visual controls and displays to communicate information and manage processes.

$ 54$ 64 -

OpEx – LSS, Lean Six Sigma Memory Jogger

Channel: OpEx Academy NZThis document offers a ready refresher with over 50 LSS topics / fundamentals1(30

slides) on Lean Six Sigma and other related best practice concepts. It includes

tools, templates, and checklists. You can also use these as 1 Point Lessons

$ 49$ 54 -

OpEx-Six Sigma – Improve Process Capability

Channel: OpEx Academy NZProcess Capability

This source outlines a three-session programme focused on determining and improving process capability, often associated with Six Sigma methodologies. The initial session introduces the process model, the relationship between Key Process Input Variables (KPIV) and Key Process Output Variables (KPOV), and the importance of measurements, including the concept of normal distribution and 3-Sigma vs 6-Sigma performance. Participants engage in an exercise using a catapult (X-Pult) to identify process variables and collect data. The second session reviews control charts, distinguishing between common cause and special cause variation, and explains process capability through the Cpk index. The final session concentrates on root cause analysis, developing improvement action plans, and implementing these changes, again using the catapult exercise to demonstrate measurable improvements in process capability.$ 49$ 54 -

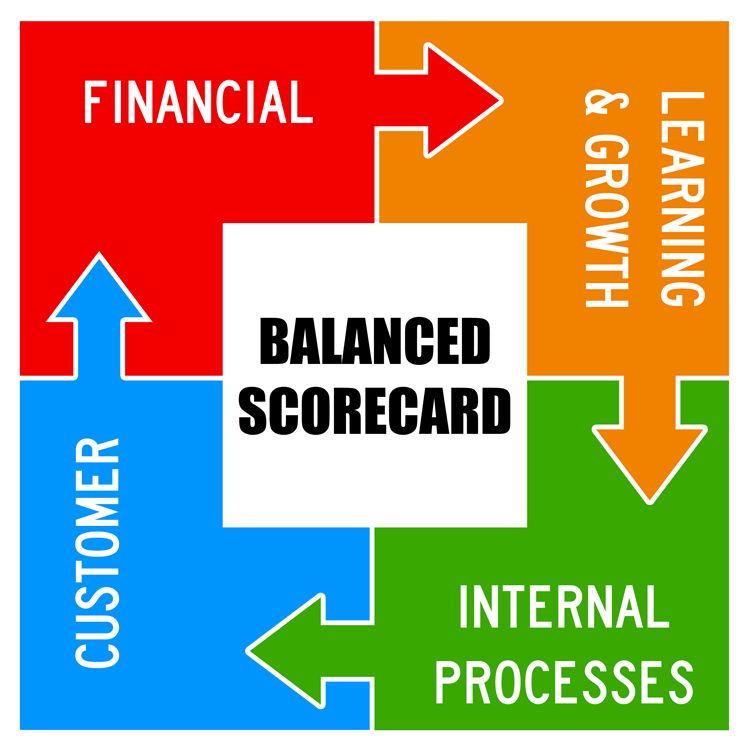

OpEx – Balanced Scorecard

Channel: OpEx Academy NZThe provided source, an excerpt from “OpEx-Balanced Scorecard.pdf” by Vishnu Rayapeddi, outlines the Balanced Scorecard (BSC) as a strategic management framework. It explains how the BSC translates an organisation’s mission and strategy into actionable performance measures, enabling effective communication and execution of strategy. The document details the four perspectives of the BSC – financial, customer, internal processes, and learning & growth – and outlines a nine-step implementation process, from organisational assessment to continuous evaluation and change. Emphasis is placed on strategic mapping, defining performance measurements (KPIs), setting targets, and initiating projects to achieve strategic objectives. Ultimately, the BSC aims to link strategy with operations and drive meaningful change for organisational success.$ 49$ 54 -

Employee Training Tracker – Excel Template

Channel: Improve Your ExcelWith this template, you’ll gain complete visibility into your team’s development progress and resource allocation.

$ 49 -

OpEx – Optimize Product Costs

Channel: OpEx Academy NZOptimizing Costs

This presentation, “OpEx – Optimise Cost,” by Vishnu Rayapeddi, outlines strategies for operational excellence focused on cost optimisation. It begins by explaining the importance of understanding customer needs and how they define quality, alongside methods for analysing cost and waste components. The document highlights various types of waste in manufacturing, such as defects, overproduction, and excessive motion, and offers practical exercises for identifying and reducing these costs. Furthermore, it introduces the concept of pull systems in production, contrasting them with traditional push systems to demonstrate their benefits in reducing operational costs and inventory. The presentation concludes by emphasising the importance of measuring results and implementing continuous improvement projects to achieve significant cost reductions and enhance customer satisfaction.$ 44$ 49 -

OpEx-Introduction to Six Sigma

Channel: OpEx Academy NZThis Six Sigma presentation is an White Belt level and meant for senior management to get a comprehensive understanding of the concept of Six Sigma and how it can help organisations improve their functioning of operations, improve quality and reduce cost.

$ 44$ 49 -

Database-Driven KPI Dashboard Excel Template | Monthly YoY Analysis | Metric Analysis by Entering Data in a Database | Performance Report

Channel: SirexcelcoDatabase-Driven KPI Dashboard

Streamline your KPI tracking with this Database-Driven KPI Dashboard Excel Template. Unlike standard templates, this tool allows you to enter data into a database, automatically calculating values and ratios for monthly and cumulative performance tracking. Easily compare your metrics against targets or analyze year-over-year (YoY) performance with dynamic charts and visualizations. Perfect for business professionals and owners looking for an intuitive way to track and compare key metrics. This template simplifies data entry, aggregates results, and provides actionable insights, making it a must-have for performance analysis.

For more details about the template, check the link below;

Content:

• Excel file compatible with Excel 2010 and higher (and with sample data)

• Professional Design

• Works both on Mac and Windows

• No installation needed. Ready to use

• Dashboard with charts

• Database-Driven KPI Dashboard Excel Template

• Easy to use

• 100% editable

• Excel file

• Instant download

• Friendly customer support for all your questions

License: Private Use (not for distribution or resale)

$ 40 -

OpEx – Standardised Work

Channel: OpEx Academy NZOpEx: Standard Work

The source, titled “OpEx – Standard Work” by Vishnu Rayapeddi, introduces Standard Work as a foundational element for achieving operational excellence in organisations. It explains that Standard Work, originating from the Toyota Production System, involves establishing agreed-upon, reliable procedures for tasks, leading to improved safety, quality, and efficiency while reducing waste and cost. The document outlines four steps to implementing Standard Work, including creating various charts, and stresses the importance of clear communication, user-friendly manuals, and regular revisions. Furthermore, it discusses the application of Standard Work in mistake-proofing and standardised training through the Training Within Industry (TWI) method, which encompasses Job Instruction (JI), Job Methods (JM), and Job Relations (JR). Finally, the source highlights the concept of Leader Standard Work, advocating for a process-dependent management system to ensure consistent leadership practices.$ 39$ 44 -

OpEx – The Lean Supply Chain

Channel: OpEx Academy NZThe Lean Supply Chain

The source, “OpEx-Lean Supply Chain.pdf” by Vishnu Rayapeddi, outlines the concept of a lean supply chain as a crucial strategy for competitive advantage in the modern, complex global market. It details how Lean Thinking principles, such as customer focus, waste reduction, and continuous improvement, can be applied across all facets of a supply chain. The document explains various components of a lean supply chain, including lean suppliers, procurement, manufacturing, warehousing, and transportation, often referencing the SCOR model for identifying areas of waste. Ultimately, the text highlights the benefits of adopting a lean approach, such as increased speed, reduced inventories and costs, and improved customer satisfaction, and includes case studies like Tesco to illustrate its successful implementation.Transcript$ 39$ 44 -

OpEx – Kaizen, Continuous Improvement

Channel: OpEx Academy NZFacilitating Kaizen

The provided document, “OpEx-Facilitate CI-Kaizen.pdf” by Vishnu Rayapeddi, introduces Kaizen, a Japanese concept meaning gradual and orderly continuous improvement. It outlines a structured approach to fostering an organisational culture of sustained improvement by eliminating waste through various activities. The text highlights different types of Kaizen activities, including “Quick and Easy Kaizen” for daily small improvements and “Kaizen Events” (also known as “Kaizen Blitz”) for targeted, accelerated improvements. The Plan-Do-Check-Act (PDCA) cycle is presented as the core process for continuous improvement, emphasising the importance of standardising new processes to prevent regression. The document also details the planning, implementation, and follow-up phases for Kaizen events, suggesting a comprehensive framework for achieving operational excellence.$ 39$ 44

-

Employee Training Tracker – Excel Template

With this template, you’ll gain complete visibility into your team’s development progress and resource allocation.

$ 49 -

OpEx-Introduction to Six Sigma

This Six Sigma presentation is an White Belt level and meant for senior management to get a comprehensive understanding of the concept of Six Sigma and how it can help organisations improve their functioning of operations, improve quality and reduce cost.

$ 44$ 49OpEx-Introduction to Six Sigma

$ 44$ 49