5S – The Myth Buster

“If you can’t master 5S, forget the rest” – Taiichi Ohno

Time and again, I keep hearing that, 5S is a cleaning programme. Some even asked why they should pay me to help clean their mess, which they can do themselves. YES, 5S does involve cleaning, but that’s not everything. Maintaining 5S, needs a structure in place and a lot of self discipline as it is connected to human behaviour.

In 2011, I was given the privilege to review a brand new book called “Clinical 5S for Healthcare by Akio Takahara” which was just published by Enna Products Corporation, USA and it is a practical guide to implementing 5S in hospitals and other medical facilities. But, the fundamental concepts apply to factories and other workplaces equally. I have chosen this topic for my article as many people misinterpret the real meaning of 5S and it is important to understand the human behaviour and the relationship to 5S. Excerpts from the book are given below:

The Relationship Between 5S and Human Error

If we examine the relationship between 5S and many accidents or incidents and errors which take place in hospitals, factories and other work areas, one thing stands out as the leading cause, which is “mis-understanding by humans”, in other words, human errors. The secret to preventing errors or incidents in any workplace is to eliminate human errors in any way possible.

Defining Human Error

The human error can be defined as “the decisions or activities of humans that hurt, damage, and discourage the functionality of safety, efficiency, comfort, profit, intention, and emotion or other human beings, animals, items, systems and the natural environment.” By Shigeru Hage, Professor at Rikkyo University, Department of Literature.

In other words “Human error is essentially a human malfunction that occurs in the process of understanding, decision-making, and carrying out an action. Humans continue to suffer from such failures no matter how much attention is given to trying to not make any mistakes” by Akio Takahara.

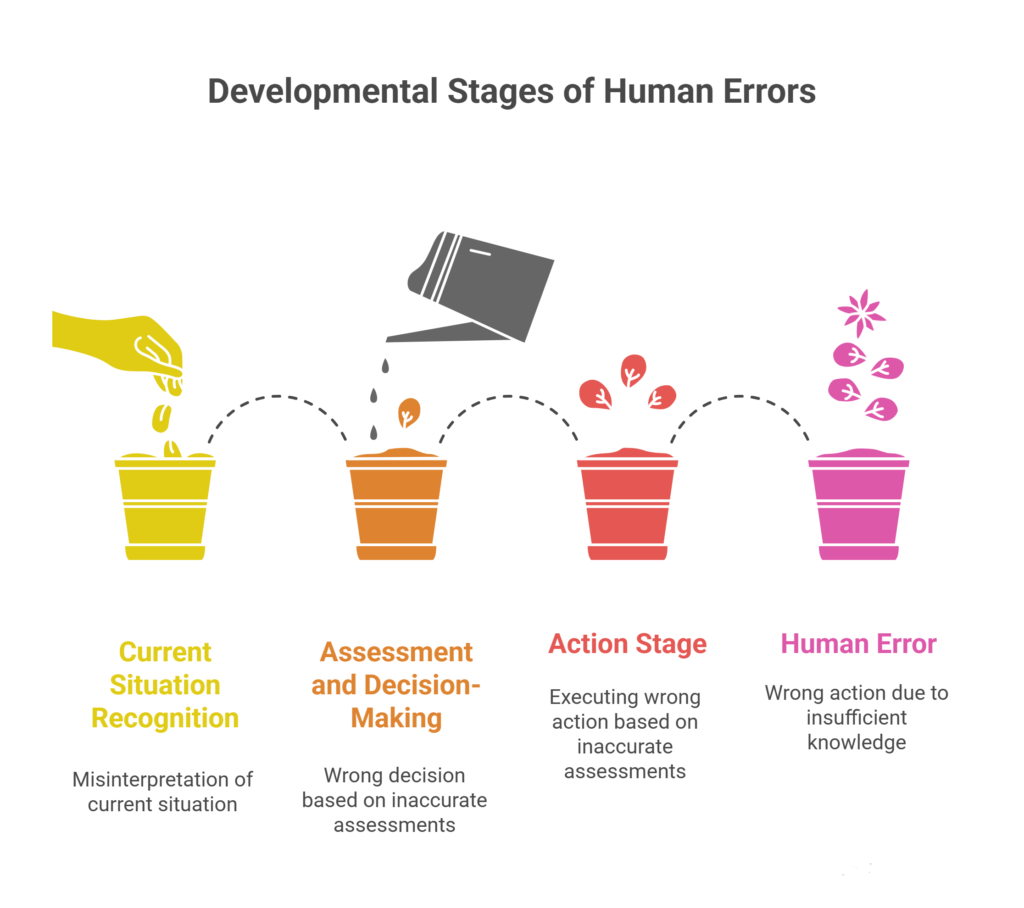

Developmental Stages of Human Errors

- Phase 1: Current situation recognition stage – errors due to wrong interpretation of current situations such as misunderstandings, preconceived notions, and sub-conscious reactions to current situation etc.

- Phase 2: Assessment and Decision-Making stage – this could be either wrong decision based on inaccurate assessments or wrong decisions due to one’s insufficient knowledge and experience, in spite of accurate assessment of current situation.

- Phase 3: Action stage – this could be executing wrong action based on inaccurate assessments or executing wrong action due to insufficient knowledge and experience, in spite of accurate assessment.

Understanding Assumptions and Misperceptions

What is an assumption? An assumption is the result of the lack of using a decision making process. In addition, such factors as habitual reactions to problems, resistance to change and over confidence in one’s actions often lead to an assumption. Humans do not perceive their reality solely based on facts collected objectively, but are able to speculate risks even in an unprecedented situation by applying their past experiences and knowledge to whatever the situation brings.

How to Reduce Misperception

Let us understand why humans perceive reality inaccurately. There are many factors to explain that. Typical reasons for that are as follows. A misunderstanding is made because:

- A & B look similar to one another

- It has been a common practice to identify A as B by mistake; therefore one continues to make the same error

- One forgets previous actions or preventative measures and continues to act as they have in the past

- One decides to make their own personal judgement in an ambiguous situation or setting

The above factors can be eliminated by creating an environment where the right decision can be made by looking at information using 5S, which is a part of Visual Management.

Origins and Evolution of 5S

The origin of 5S seems rooted in the works of two American pioneers who were scrupulously studied by Japanese managers. These were Frederick W. Taylor’s Scientific Management (1911) and Henry Ford (1922). Indeed, Ford’s CANDO program (Cleaning up, Arranging, Neatness, Discipline, Ongoing Improvement), which builds on Taylor’s work, appears as the obvious origin for 5S.

The first reference you can access is by Takashi Osada: The 5S’s – Five Keys to a Total Quality Environment. Osada is a founder of the 5S concept for industry use. He was working on TPM thus the book is TPM-oriented. The safety aspect is also included. The next reference is by Hiroyuki Hirano. Hirano is a JIT consultant thus his books are all JIT-oriented.

The 5S concepts were definitely not developed at Toyota (read Workplace Management by Taiichi Ohno). The first application of 5S in business is for safety purpose. Studies show that introduction of 2S (Sort and Set-to-Order) in 1946 reduced injuries by 56%, and the introduction of the next 2S’s (Shine and Standardise) in early 1960’s reduced injuries by 68% and improved productivity by 360%. When the 5th S (Sustain) was also introduced in early 1980’s injuries continued to reduce (51%) and productivity continued to improve (141%). The 6th S (Safety) was introduced in early 2000’s.

The Meaning of the 6S’s

- Sort – Distinguish between what is needed and not needed and to remove the latter.

- Set-in-Order – Enforce a place for everything and everything in its place.

- Shine – Clean up the workplace and look for ways to keep it clean.

- Standardise – Maintain and monitor adherence to the first three S’s.

- Sustain – Follow the rules to keep the workplace 6S-right—“maintain the gain”.

- Safety – Eliminate hazards. (We added this sixth “S” so we could maintain the focus on Safety within our Lean events and embed safe conditions into all our improvements.)