-

OpEx-Competitive Manufacturing

Competitive Manufacturing: Your Gateway to Operational Excellence

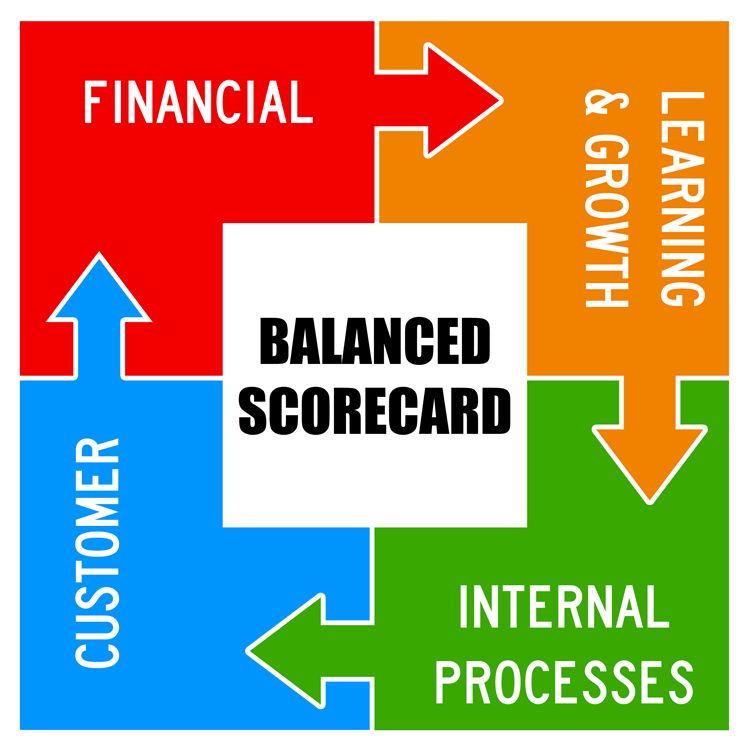

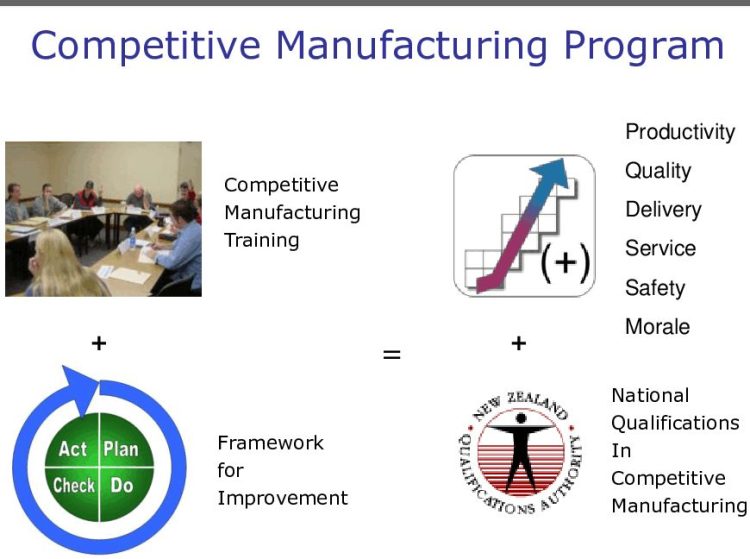

This training material, titled “Competitive Manufacturing” by Vishnu Rayapeddi, introduces the concept of Operational Excellence. It outlines a comprehensive programme designed to equip participants with the knowledge, tools, and methods to significantly improve workplaces, leading to nationally recognised certification. The core focus is on identifying and eliminating operational waste—such as defects, overproduction, and unnecessary motion—to achieve “World Class” business performance through increased cost-effectiveness, higher quality, and faster, more consistent production. The material details a structured change management model, emphasising the importance of defining changes, establishing Key Performance Indicators (KPIs), engaging stakeholders, and meticulously planning and monitoring implementation through various tools like Gantt Charts and Visual Management Systems. Ultimately, it aims to transform businesses by fostering a culture of continuous improvement and value creation for the customer.$ 59$ 69OpEx-Competitive Manufacturing

$ 59$ 69 -

OpEx-Introduction to Six Sigma

This Six Sigma presentation is an White Belt level and meant for senior management to get a comprehensive understanding of the concept of Six Sigma and how it can help organisations improve their functioning of operations, improve quality and reduce cost.

$ 44$ 49OpEx-Introduction to Six Sigma

$ 44$ 49 -

OpEx – Inventory Management

This source provides an extensive overview of inventory management within supply chain fundamentals. It introduces Vishnu Rayapeddi as the author, highlighting their significant experience and qualifications in the field. The text thoroughly defines inventory and inventory management, outlining key objectives such as customer service and cost minimisation. Various types of inventory are explored, alongside the costs associated with inventory, including holding, ordering, and shortage costs. The document also differentiates between independent and dependent demand and explains various order quantity strategies, focusing on the Economic Order Quantity (EOQ) model and the Quantity Discount Model, complete with practical examples. Furthermore, it details ABC analysis for inventory categorisation, its procedural steps, and implications for inventory management policies, including cycle counting and different inventory valuation methods like FIFO, LIFO, and Weighted Average. Finally, the text briefly touches upon Kanban systems as a method for production control.

$ 39$ 44OpEx – Inventory Management

$ 39$ 44