-

Non Profit KPI Dashboard Excel Template, KPI Report, Dynamic Editable Performance Tracking Tool, Reporting File, Ready to Download

Channel: SirexcelcoMake managing your nonprofit’s performance easier with this dynamic and editable Non Profit KPI Dashboard Excel Template.

Whether you’re tracking donations, volunteer hours, or program impact, this template helps you stay on top of key metrics and make data-driven decisions.

For more details about the template, check the link below;

With this easy-to-use tool, you can customize the dashboard to fit your nonprofit’s unique goals, track progress, and generate clear reports. Ideal for nonprofit organizations, charities, and social enterprises, it saves you time and helps keep your team focused on what matters.

Perfect for nonprofit managers, directors, and anyone responsible for tracking performance and reporting, this template helps simplify your workload.

Key Features:

Fully customizable and editable Excel dashboard

Tracks key nonprofit KPIs like donations, volunteers, and program results

Simple design for easy use, no advanced Excel skills needed

Ready to download and start using immediately

Ideal for nonprofits, charities, and social impact projects

Content:

• Excel file compatible with Excel 2010 and higher (and with sample data)

• Professional Design

• Works both on Mac and Windows

• No installation needed. Ready to use

• Dashboard with charts

• Non-Profit KPI Dashboard Template

• Easy to use

• 100% editable

• Excel file

• Instant download

• Friendly customer support for all your questions

License: Private Use (not for distribution or resale)

$ 35 -

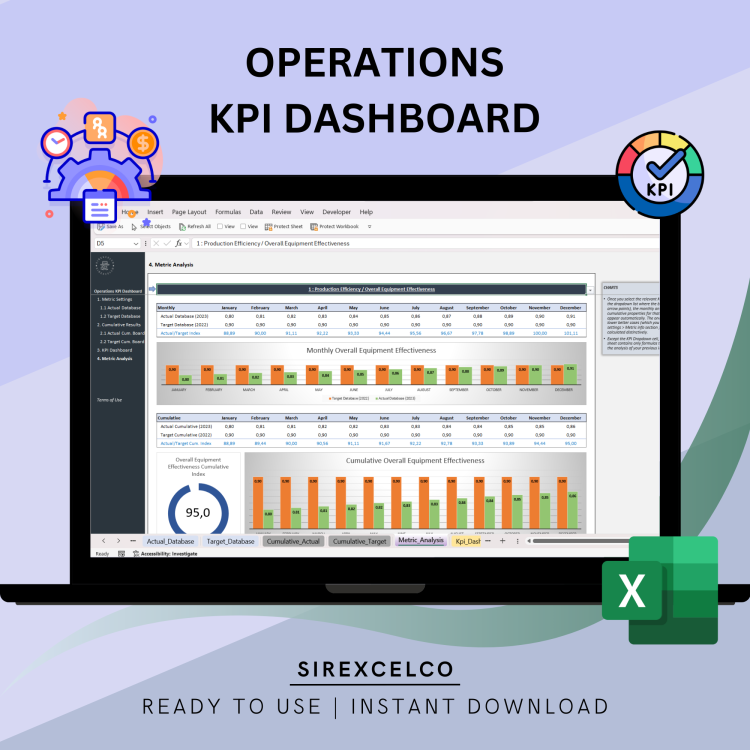

Operations KPI Dashboard Excel Template | Spreadsheet for Business Management | Performance Tracking | Editable Operations KPI Dashboard

Channel: SirexcelcoThis Operations KPI Dashboard Excel Template is perfect for tracking and visualizing your business performance metrics.

For more details about the template, check the link below;

Whether you’re managing a small business or a large enterprise, this customizable Excel dashboard helps you monitor key performance indicators (KPIs) in real-time. With easy-to-use formulas and pre-built charts, you can efficiently track and analyze data to make informed decisions. Download this template today and take control of your business analytics with a professional, user-friendly tool.

Content:

• Excel file compatible with Excel 2010 and higher (and with sample data)

• Professional Design

• Works both on Mac and Windows

• No installation needed. Ready to use

• Dashboard with charts

• Operations KPI Dashboard

• Easy to use

• 100% editable

• Excel file

• Instant download

• Friendly customer support for all your questions

License: Private Use (not for distribution or resale)

$ 35 -

OpEx – Apply Six Sigma to Process Control and Improvement

Channel: OpEx Academy NZSix Sigma for Process Control and Improvement

This document outlines a comprehensive Six Sigma training programme, focusing on process control and improvement using the DMAIC (Define, Measure, Analyse, Improve, Control) methodology. The material introduces Six Sigma as a framework for reducing variation and improving customer satisfaction through data-driven problem-solving, aiming for a performance level of 3.4 defects per million opportunities. It details each phase of DMAIC, providing specific tools and techniques, such as project charters, data collection plans, cause and effect diagrams, and control charts. The training incorporates practical simulations, like the “X Pult” exercise, to demonstrate the application of these methods in identifying problems, measuring performance, analysing root causes, implementing solutions, and sustaining improvements within an organisational context.$ 59$ 64 -

OpEx – Balanced Scorecard Self-Assessment

Channel: OpEx Academy NZUnderstand your current situation with respect to measurement to set goals for improvement.

$ 24$ 29 -

OpEx – Business Integration Excellence Assessment

Channel: OpEx Academy NZUnderstand the current state of your business integration to set improvement goals

$ 29$ 34 -

OpEx – Inventory Management

Channel: OpEx Academy NZThis source provides an extensive overview of inventory management within supply chain fundamentals. It introduces Vishnu Rayapeddi as the author, highlighting their significant experience and qualifications in the field. The text thoroughly defines inventory and inventory management, outlining key objectives such as customer service and cost minimisation. Various types of inventory are explored, alongside the costs associated with inventory, including holding, ordering, and shortage costs. The document also differentiates between independent and dependent demand and explains various order quantity strategies, focusing on the Economic Order Quantity (EOQ) model and the Quantity Discount Model, complete with practical examples. Furthermore, it details ABC analysis for inventory categorisation, its procedural steps, and implications for inventory management policies, including cycle counting and different inventory valuation methods like FIFO, LIFO, and Weighted Average. Finally, the text briefly touches upon Kanban systems as a method for production control.

$ 39$ 44 -

OpEx – JIT Heijunka, Load Levelling

Channel: OpEx Academy NZHeijunka: Production Leveling This document

from OpExNZL, authored by Vishnu Rayapeddi, provides a comprehensive overview

of Heijunka, or production levelling, as a gateway to operational excellence.

It outlines prerequisites for implementing Heijunka, including 5S, Standard

Work, and SMED (Quick Changeovers). The core concepts of Just-In-Time (JIT)

manufacturing are thoroughly explained, encompassing Takt Time, Continuous

Flow, and Pull Systems. The document details the benefits, applications, and

success factors for each of these JIT principles, offering practical examples

and visual aids like cellular manufacturing layouts and Kanban systems.

Finally, it focuses on Production Levelling, contrasting it with batch

manufacturing, demonstrating its benefits in managing customer demand and variations,

and outlining steps for its incorporation, such as calculating Takt Time and

Pitch and using a Leveling Box.$ 34$ 39 -

OpEx – Kaizen, Continuous Improvement

Channel: OpEx Academy NZFacilitating Kaizen

The provided document, “OpEx-Facilitate CI-Kaizen.pdf” by Vishnu Rayapeddi, introduces Kaizen, a Japanese concept meaning gradual and orderly continuous improvement. It outlines a structured approach to fostering an organisational culture of sustained improvement by eliminating waste through various activities. The text highlights different types of Kaizen activities, including “Quick and Easy Kaizen” for daily small improvements and “Kaizen Events” (also known as “Kaizen Blitz”) for targeted, accelerated improvements. The Plan-Do-Check-Act (PDCA) cycle is presented as the core process for continuous improvement, emphasising the importance of standardising new processes to prevent regression. The document also details the planning, implementation, and follow-up phases for Kaizen events, suggesting a comprehensive framework for achieving operational excellence.$ 39$ 44 -

OpEx – Lean Execution-The Success Mantra

Channel: OpEx Academy NZLean Execution

This comprehensive source, “OpEx – Lean Execution,” authored by Vishnu Rayapeddi, serves as a gateway to operational excellence through the application of Lean principles. It meticulously outlines a roadmap for understanding and implementing Lean methodologies, beginning with a foundational explanation of what Lean is and its core concept of eliminating waste to maximise customer value. The text places significant emphasis on “The Toyota Way” and its 14 principles, presenting them as a blueprint for achieving continuous improvement and fostering a culture of respect for people. Furthermore, the source addresses common reasons why Lean implementations fail, such as lack of vision or management commitment, and offers strategies for managing change effectively within an organisation. It then broadens its scope to include other business excellence philosophies like Six Sigma, Theory of Constraints, and Total Quality Management, highlighting their individual strengths and the potential benefits of a combined approach. Finally, the document details the practical steps involved in executing Lean, including assessment tools, the importance of long-term commitment, documentation, and the crucial role of people development and leadership in sustaining a Lean culture.$ 69$ 74 -

OpEx – Lean JIT Kanban Systems

Channel: OpEx Academy NZKanban System Implementation

This source, titled “OpEx-KanbanSystems.pdf” by Vishnu Rayapeddi, provides a comprehensive overview of Kanban implementation within operational excellence frameworks. It explores the historical origins of Kanban from its roots in Toyota’s production system to its purpose in modern manufacturing. The document details the mechanics of Kanban, including visual systems, planning and scheduling integration, and various types such as withdrawal, production, and signal Kanbans. Furthermore, it highlights the significant benefits of adopting a Kanban system, such as inventory reduction and improved flow, and offers a seven-step guide to successful implementation, concluding with a practical case study for calculating Kanban numbers.$ 39$ 44 -

OpEx – Lean JIT, Just In Time

Channel: OpEx Academy NZDeveloping a Just in Time System

This resource, “Develop a Just in Time System” by Vishnu Rayapeddi, offers a comprehensive guide to implementing Just-in-Time (JIT) operational strategies. It begins by defining JIT as a system that ensures products are delivered precisely when and where they are needed, highlighting its benefits such as reduced costs and increased customer satisfaction. The material then explores the distinction between push and pull systems for creating product flow, advocating for the latter’s efficiency in lowering inventory. Key performance indicators like Takt Time, inventory turns, and DIFOTIS (Delivered in Full, On Time, In Spec) are introduced as crucial for monitoring success. The document further outlines various Kanban systems—including production, withdrawal, signal, multi-bin, and e-Kanban—as vital tools for managing material flow, along with CONWIP and FIFO systems. Finally, it presents a structured approach to implementing JIT through workplace projects, detailing evidence requirements for designing, implementing, and monitoring the system.$ 29$ 34 -

OpEx – Lean Leadership Survey Check-List

Channel: OpEx Academy NZBENEFITS OF THIS WORD DOCUMENT

- Understand the Level of Leadership before any transformational activity

$ 19$ 24

-

OpEx – Inventory Management

This source provides an extensive overview of inventory management within supply chain fundamentals. It introduces Vishnu Rayapeddi as the author, highlighting their significant experience and qualifications in the field. The text thoroughly defines inventory and inventory management, outlining key objectives such as customer service and cost minimisation. Various types of inventory are explored, alongside the costs associated with inventory, including holding, ordering, and shortage costs. The document also differentiates between independent and dependent demand and explains various order quantity strategies, focusing on the Economic Order Quantity (EOQ) model and the Quantity Discount Model, complete with practical examples. Furthermore, it details ABC analysis for inventory categorisation, its procedural steps, and implications for inventory management policies, including cycle counting and different inventory valuation methods like FIFO, LIFO, and Weighted Average. Finally, the text briefly touches upon Kanban systems as a method for production control.

$ 39$ 44OpEx – Inventory Management

$ 39$ 44