-

OpEx – PFEP, Plan For Every Part

Plan for Every Part

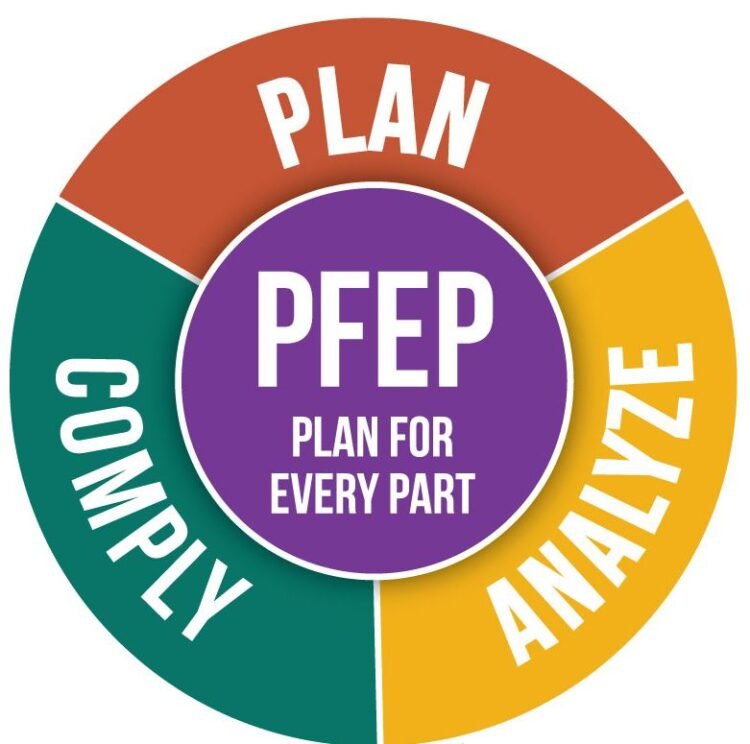

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.$ 20$ 25OpEx – PFEP, Plan For Every Part

$ 20$ 25 -

OpEx – Site Review Check-List (XLS)

Understand the current state of your organisation to move forward with any improvement activities

$ 29$ 34OpEx – Site Review Check-List (XLS)

$ 29$ 34 -

OpEx – Six Sigma – Design of Experiments

Design of Experiments

This collection of materials introduces the concept of Design of Experiments (DOE) as a methodology for operational excellence. The content outlines a structured approach to experimentation, moving from problem identification and basic experimentation methods like Trial and Error and One-Variable-At-a-Time (OVAT) to more sophisticated techniques. It then progresses to Full Factorial DOE, which systematically examines all factor combinations, and subsequently to Fractional Factorial DOE, a more efficient method that sacrifices some interaction information for reduced testing. The X Pult simulation is consistently used as a practical, hands-on exercise throughout the sessions to illustrate these experimental design principles and their application in achieving consistent and accurate results. The sessions also cover essential terminology like replicates, randomisation, and blocking, along with tools and templates for data collection and analysis.$ 29$ 34