OpEx – PFEP, Plan For Every Part

$ 20$ 25 (-20%)

Plan for Every Part

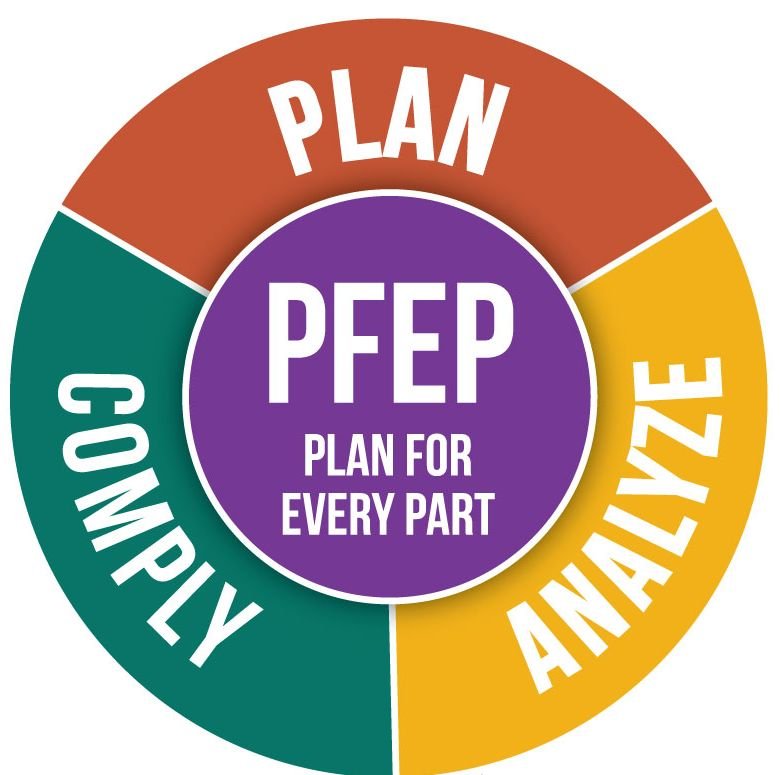

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.

Benefits of PFEP PPT Document

- Plan for Every Part – How to Implement

- Materials Control in Supply Chain

- Lean Supply Chain – Planning for each part

Supply Chain Resilience PPT Description

This product (OpEx-PI: PFEP – Plan for Every Part Presentation) is a 33-slide PPT PowerPoint presentation slide deck (PPT), which you can download immediately upon purchase.

This presentation has 32 slides in all and covers the following topics:

- Why PFEP – Benefits

- Develop an Implementation Plan

- Create a future state VSM

- Plan For Every Part – Implementation

- Step 1: Create PFEP Database – Current State (Part, Container, Shipping, Supplier, Consumption, Part Readiness and Cost & Inventory)

- Step 2: Create a “PLAN” for Every Part

- Step 3: Sustaining and Maintaining Integrity of the Database PFEP Change Request Form (Sample Form Attached)

- Why a Change Request Form?

Keys to Success

A Word Document showing the Change Request form is attached to this document.

This presentation provides a comprehensive guide to establishing a Plan for Every Part (PFEP) system, which is crucial for optimizing material handling and inventory management. It emphasizes the importance of creating a lean material-handling system, storing all pertinent data in a central location, and sorting parts data by various categories. The PPT outlines the steps necessary to develop and maintain a PFEP database, ensuring quick responses to

operational questions and extending the lean material-handling system across

multiple facilities.

The document delves into the creation of a Future State Value Stream Map (VSM), a tool that visualizes the flow of materials and information. This map helps identify production steps, storage methods, and delivery processes, providing a clear roadmap for future improvements. The presentation also highlights the need for a user-friendly database with sorting capabilities, which can be integrated into the company’s MRP or ERP system for better data management and accuracy.

Sustaining and maintaining the integrity of the PFEP database is a continuous process. The presentation stresses the importance of regular updates, modifications, and the involvement of a dedicated team to ensure the system’s effectiveness. By instituting guidelines for documenting changes and establishing a PFEP manager, companies can ensure that their material handling

system remains efficient and up-to-date, ultimately leading to significant improvements in operational excellence.

Source: Best Practices in Supply Chain Resilience, Lean Supply Chain

PowerPoint Slides: PSL-PI: PFEP – Plan for Every Part Presentation PowerPoint

(PPT) Presentation Slide Deck, OpEx Academy NZ

Shipping Policy

Documents once purchased can not be returned and refund requests are not entertained. So, please check all the details before purchasing and downloading the training materials.

Refund Policy

Once purchased, no refinds are allowed. Any queries one may have can be answered prir to the purchase and downloads.

Cancellation / Return / Exchange Policy

No cancellation or returns are accepted once the documents are purchased and downloaded.

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.