-

Project POAP – MS PowerPoint template – Both editable & easy to use

Channel: i_Pro_PM_TemplatesMicrosoft PowerPoint template both editable & easy to use, offers a quick way to construct a PPT Project Plan On a Page ( POaP ) for stakeholders

$ 30$ 40 -

Waterfall Project Planner, Project Plan Gantt Chart & Resource Cost / Budget / Revenue Tracker – MS Microsoft Excel (x2)

Channel: i_Pro_PM_TemplatesWaterfall Project Planner with Plan Gantt View and Project Resource Cost Tracker – MS Microsoft Excel Template (2 comprehensive templates for the price of one)

$ 30$ 40 -

PRINCE2 7th Edition Planner MS Templates Download – Both Microsoft Project MPP msp & ms Excel and Word Formats – Prince2

Channel: i_Pro_PM_TemplatesPRINCE2 7th Edition MS Templates Download – Microsoft Project MPP msp ms Excel and Word Formats – Prince2 Template Toolkit

$ 40$ 50 -

Project Management Template, Editable Excel Planner, Gantt Chart for Status Reports, Costing Delivery, Bids

Channel: i_Pro_PM_TemplatesPrince2 & Agile Project Management Templates | Editable Excel Planner, Gantt Chart for Status Reports, Costing Delivery, Bids

$ 30$ 40 -

Microsoft Excel Editable Weekly Status Report (internal external reporting) including Plan on a Page and RAIDs log etc.

Channel: i_Pro_PM_TemplatesExcel Weekly Status Report template with POaP, RAID log, burndown chart. For Agile or PRINCE2 projects. Editable for internal/external reporting.

$ 30$ 40 -

Programme, Project Benefits Realization Tracker MS Template for Recording & Tracking project benefits, baseline & status

Channel: i_Pro_PM_TemplatesMS Excel template for Programme & Project Benefits Realization tracking. Record benefits, baselines, targets & RAG status to monitor project outcomes.

$ 30$ 40 -

Prince2 & Agile Excel RAID log template, track project Risks, Assumptions, Issues, Dependencies (plus other key logs)

Channel: i_Pro_PM_TemplatesPrince2 & Agile Excel RAID log template to track Risks, Assumptions, Issues, Dependencies & more. Editable, comprehensive & ideal for project managers.

$ 30$ 40 -

Project Programme Team Onboarding Kit Microsoft PowerPoint Editable Template

Channel: i_Pro_PM_TemplatesEditable MS PowerPoint Project & Programme Team Onboarding Kit. Ready-made slides to introduce new team members, project goals, roles & processes.

$ 30$ 40 -

Project Programme Team Kick Off PowerPoint Microsoft Editable Template

Channel: i_Pro_PM_TemplatesReady made Project Programme Kick Off template to be tailored as required for project delivery. Helps to structure your thinking by providing guidance and slides for key kick off focus areas. A useful template aid to drive one of the key tasks of a project that can often be overlooked.

$ 30$ 40 -

OpEx – JIT Heijunka, Load Levelling

Channel: OpEx Academy NZHeijunka: Production Leveling This document

from OpExNZL, authored by Vishnu Rayapeddi, provides a comprehensive overview

of Heijunka, or production levelling, as a gateway to operational excellence.

It outlines prerequisites for implementing Heijunka, including 5S, Standard

Work, and SMED (Quick Changeovers). The core concepts of Just-In-Time (JIT)

manufacturing are thoroughly explained, encompassing Takt Time, Continuous

Flow, and Pull Systems. The document details the benefits, applications, and

success factors for each of these JIT principles, offering practical examples

and visual aids like cellular manufacturing layouts and Kanban systems.

Finally, it focuses on Production Levelling, contrasting it with batch

manufacturing, demonstrating its benefits in managing customer demand and variations,

and outlining steps for its incorporation, such as calculating Takt Time and

Pitch and using a Leveling Box.$ 34$ 39 -

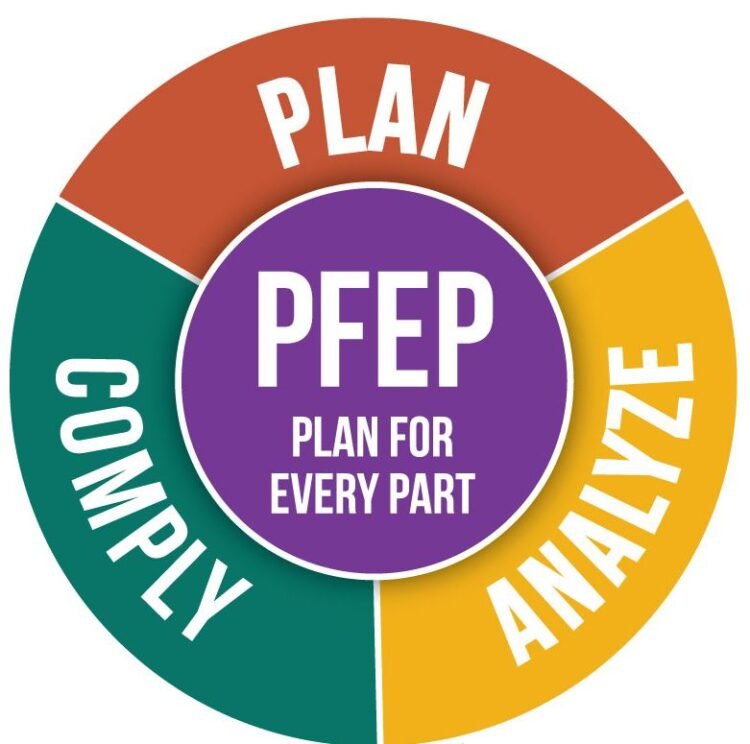

OpEx – PFEP, Plan For Every Part

Channel: OpEx Academy NZPlan for Every Part

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.$ 20$ 25 -

OpEx – Poka-Yoke (Mistake Proofing)

Channel: OpEx Academy NZPoka-Yoke: The Art of Mistake Proofing

The source, titled “OpEx – Poka Yoke Mistake proofing.pdf,” outlines a comprehensive approach to achieving operational excellence through mistake-proofing, also known as Poka-Yoke. It emphasises that defects account for a significant portion of production costs and stresses the importance of preventing errors at the source rather than merely inspecting them out. The document introduces principles for achieving zero defects, focusing on process control over individual blame, and explores various categories of error and their prevention strategies. It details six mistake-proofing techniques—elimination, replacement, prevention, facilitation, detection, and mitigation—providing examples for each. Finally, it presents a seven-step framework for implementing error-proofing and a five-part project methodology for designing defects out of processes, encouraging continuous improvement and team invol$ 34$ 39

-

OpEx – PFEP, Plan For Every Part

Plan for Every Part

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.$ 20$ 25OpEx – PFEP, Plan For Every Part

$ 20$ 25