-

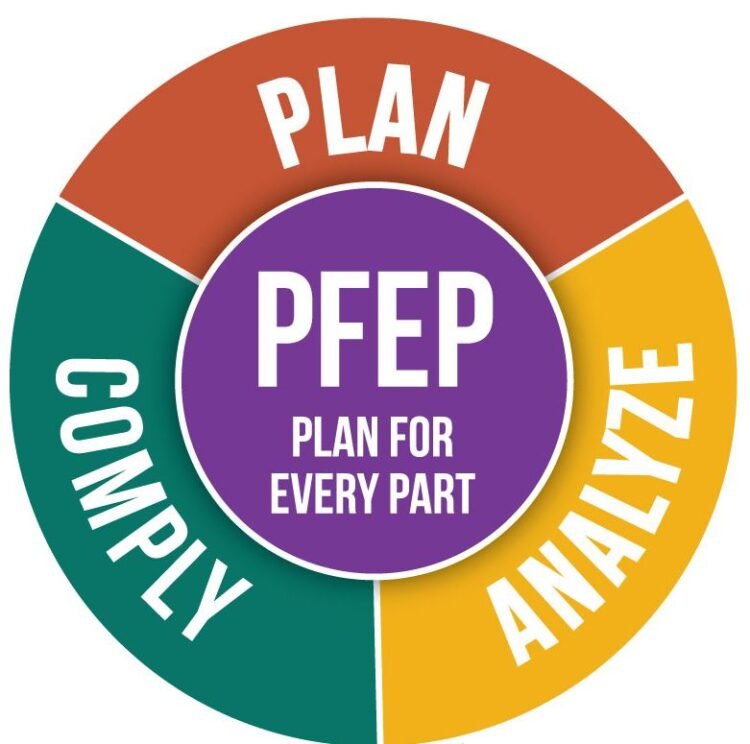

OpEx – PFEP, Plan For Every Part

Channel: OpEx Academy NZPlan for Every Part

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.$ 20$ 25 -

OpEx – Poka-Yoke (Mistake Proofing)

Channel: OpEx Academy NZPoka-Yoke: The Art of Mistake Proofing

The source, titled “OpEx – Poka Yoke Mistake proofing.pdf,” outlines a comprehensive approach to achieving operational excellence through mistake-proofing, also known as Poka-Yoke. It emphasises that defects account for a significant portion of production costs and stresses the importance of preventing errors at the source rather than merely inspecting them out. The document introduces principles for achieving zero defects, focusing on process control over individual blame, and explores various categories of error and their prevention strategies. It details six mistake-proofing techniques—elimination, replacement, prevention, facilitation, detection, and mitigation—providing examples for each. Finally, it presents a seven-step framework for implementing error-proofing and a five-part project methodology for designing defects out of processes, encouraging continuous improvement and team invol$ 34$ 39 -

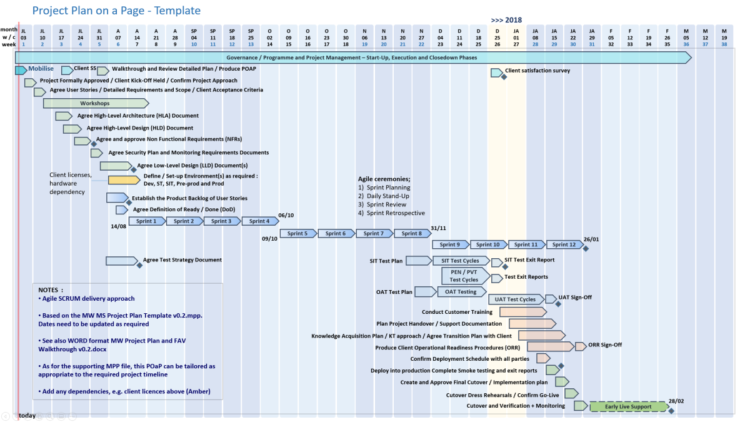

130+ PM Templates | FREE Upgrades and Additions | Agile, Waterfall & Prince2 Project Management Templates

Channel: i_Pro_PM_Templates130+ PM Templates | FREE Upgrades and Additions | Agile, Waterfall & Prince2 Project Management Templates | Microsoft Project Excel PowerPoint + RAID Log, POaP, Gantt View with Resource Cost Tracker etc.

FREE template upgrades for life available after purchase. This package contains ALL the PM templates offered by the seller,

The PM templates download link is contained in an ‘officedocdepot’ text file made available immediately after your purchase.

$ 89$ 120 -

OpEx – Optimize Product Costs

Channel: OpEx Academy NZOptimizing Costs

This presentation, “OpEx – Optimise Cost,” by Vishnu Rayapeddi, outlines strategies for operational excellence focused on cost optimisation. It begins by explaining the importance of understanding customer needs and how they define quality, alongside methods for analysing cost and waste components. The document highlights various types of waste in manufacturing, such as defects, overproduction, and excessive motion, and offers practical exercises for identifying and reducing these costs. Furthermore, it introduces the concept of pull systems in production, contrasting them with traditional push systems to demonstrate their benefits in reducing operational costs and inventory. The presentation concludes by emphasising the importance of measuring results and implementing continuous improvement projects to achieve significant cost reductions and enhance customer satisfaction.$ 44$ 49 -

OpEx – Process Optimization using Six Sigma Techniques

Channel: OpEx Academy NZOptimizing Costs

This presentation, “OpEx – Optimise Cost,” by Vishnu Rayapeddi, outlines strategies for operational excellence focused on cost optimisation. It begins by explaining the importance of understanding customer needs and how they define quality, alongside methods for analysing cost and waste components. The document highlights various types of waste in manufacturing, such as defects, overproduction, and excessive motion, and offers practical exercises for identifying and reducing these costs. Furthermore, it introduces the concept of pull systems in production, contrasting them with traditional push systems to demonstrate their benefits in reducing operational costs and inventory. The presentation concludes by emphasising the importance of measuring results and implementing continuous improvement projects to achieve significant cost reductions and enhance customer satisfaction.$ 69$ 74 -

OpEx – Apply Six Sigma to Process Control and Improvement

Channel: OpEx Academy NZSix Sigma for Process Control and Improvement

This document outlines a comprehensive Six Sigma training programme, focusing on process control and improvement using the DMAIC (Define, Measure, Analyse, Improve, Control) methodology. The material introduces Six Sigma as a framework for reducing variation and improving customer satisfaction through data-driven problem-solving, aiming for a performance level of 3.4 defects per million opportunities. It details each phase of DMAIC, providing specific tools and techniques, such as project charters, data collection plans, cause and effect diagrams, and control charts. The training incorporates practical simulations, like the “X Pult” exercise, to demonstrate the application of these methods in identifying problems, measuring performance, analysing root causes, implementing solutions, and sustaining improvements within an organisational context.$ 59$ 64 -

OpEx – LSS, Lean Six Sigma Memory Jogger

Channel: OpEx Academy NZThis document offers a ready refresher with over 50 LSS topics / fundamentals1(30

slides) on Lean Six Sigma and other related best practice concepts. It includes

tools, templates, and checklists. You can also use these as 1 Point Lessons

$ 49$ 54 -

OpEx – Balanced Scorecard Self-Assessment

Channel: OpEx Academy NZUnderstand your current situation with respect to measurement to set goals for improvement.

$ 24$ 29 -

OpEx – Site Review Check-List (XLS)

Channel: OpEx Academy NZUnderstand the current state of your organisation to move forward with any improvement activities

$ 29$ 34 -

OpEx – Lean Manufacturing Assessment

Channel: OpEx Academy NZKnow where you are today before embarking on an improvement plan and set goals

$ 29$ 34 -

OpEx – Business Integration Excellence Assessment

Channel: OpEx Academy NZUnderstand the current state of your business integration to set improvement goals

$ 29$ 34 -

OpEx – Lean Leadership Survey Check-List

Channel: OpEx Academy NZBENEFITS OF THIS WORD DOCUMENT

- Understand the Level of Leadership before any transformational activity

$ 19$ 24

-

OpEx – PFEP, Plan For Every Part

Plan for Every Part

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.$ 20$ 25OpEx – PFEP, Plan For Every Part

$ 20$ 25 -

OpEx – Site Review Check-List (XLS)

Understand the current state of your organisation to move forward with any improvement activities

$ 29$ 34OpEx – Site Review Check-List (XLS)

$ 29$ 34