-

OpEx-SCM Fundamentals – Aggregate Planning

Aggregate Planning for Supply Chains

The source, titled “OpEx – SCM Funda3 Planning.pdf” by Vishnu Rayapeddi, provides a comprehensive overview of aggregate planning within supply chain management. It outlines the requirements, tasks, responsibilities, and relationships involved in this crucial planning process, which typically spans 3 to 18 months. The document details various aggregate planning goals such as meeting demand and minimising costs, and explores different pure strategies including adjusting capacity options (e.g., inventory levels, workforce size, subcontracting) and demand options (e.g., influencing demand, backordering). It further presents production strategies like chase, level, subcontracting, and hybrid approaches, along with their respective advantages and disadvantages, before discussing aggregate planning methods such as graphical techniques and mathematical models. Finally, the source touches upon controlling labour costs in service firms and the concept of yield management$ 20$ 24 -

OpEx-Competitive Manufacturing

Competitive Manufacturing: Your Gateway to Operational Excellence

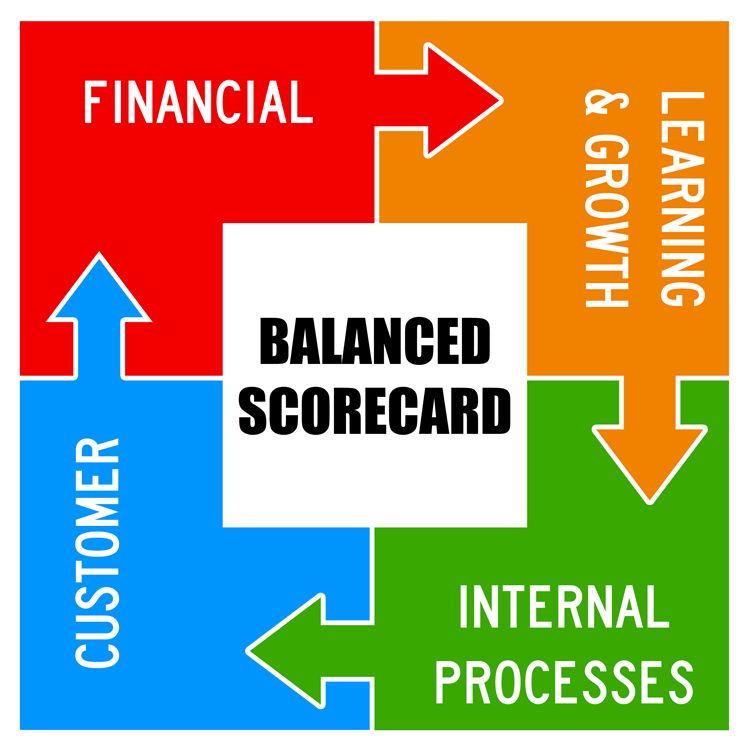

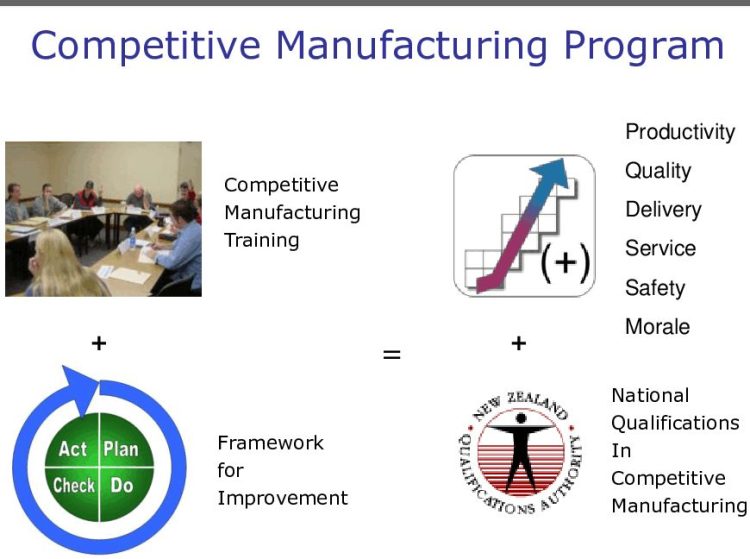

This training material, titled “Competitive Manufacturing” by Vishnu Rayapeddi, introduces the concept of Operational Excellence. It outlines a comprehensive programme designed to equip participants with the knowledge, tools, and methods to significantly improve workplaces, leading to nationally recognised certification. The core focus is on identifying and eliminating operational waste—such as defects, overproduction, and unnecessary motion—to achieve “World Class” business performance through increased cost-effectiveness, higher quality, and faster, more consistent production. The material details a structured change management model, emphasising the importance of defining changes, establishing Key Performance Indicators (KPIs), engaging stakeholders, and meticulously planning and monitoring implementation through various tools like Gantt Charts and Visual Management Systems. Ultimately, it aims to transform businesses by fostering a culture of continuous improvement and value creation for the customer.$ 59$ 69OpEx-Competitive Manufacturing

$ 59$ 69