-

OpEx – JIT Heijunka, Load Levelling

Channel: OpEx Academy NZHeijunka: Production Leveling This document

from OpExNZL, authored by Vishnu Rayapeddi, provides a comprehensive overview

of Heijunka, or production levelling, as a gateway to operational excellence.

It outlines prerequisites for implementing Heijunka, including 5S, Standard

Work, and SMED (Quick Changeovers). The core concepts of Just-In-Time (JIT)

manufacturing are thoroughly explained, encompassing Takt Time, Continuous

Flow, and Pull Systems. The document details the benefits, applications, and

success factors for each of these JIT principles, offering practical examples

and visual aids like cellular manufacturing layouts and Kanban systems.

Finally, it focuses on Production Levelling, contrasting it with batch

manufacturing, demonstrating its benefits in managing customer demand and variations,

and outlining steps for its incorporation, such as calculating Takt Time and

Pitch and using a Leveling Box.$ 34$ 39 -

OpEx – PFEP, Plan For Every Part

Channel: OpEx Academy NZPlan for Every Part

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.$ 20$ 25 -

OpEx – Poka-Yoke (Mistake Proofing)

Channel: OpEx Academy NZPoka-Yoke: The Art of Mistake Proofing

The source, titled “OpEx – Poka Yoke Mistake proofing.pdf,” outlines a comprehensive approach to achieving operational excellence through mistake-proofing, also known as Poka-Yoke. It emphasises that defects account for a significant portion of production costs and stresses the importance of preventing errors at the source rather than merely inspecting them out. The document introduces principles for achieving zero defects, focusing on process control over individual blame, and explores various categories of error and their prevention strategies. It details six mistake-proofing techniques—elimination, replacement, prevention, facilitation, detection, and mitigation—providing examples for each. Finally, it presents a seven-step framework for implementing error-proofing and a five-part project methodology for designing defects out of processes, encouraging continuous improvement and team invol$ 34$ 39 -

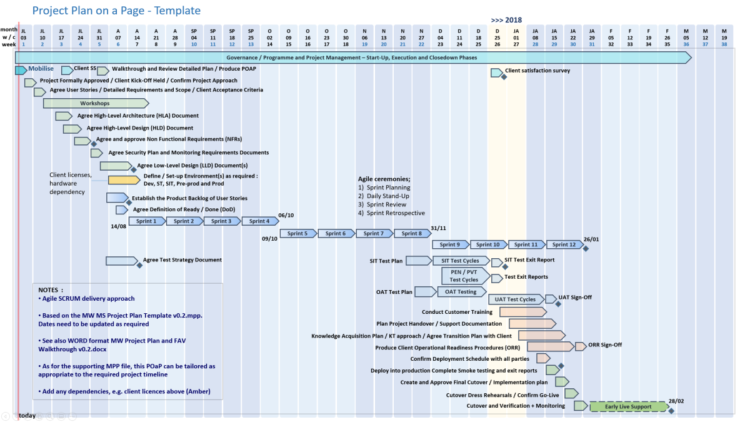

130+ PM Templates | FREE Upgrades and Additions | Agile, Waterfall & Prince2 Project Management Templates

Channel: i_Pro_PM_Templates130+ PM Templates | FREE Upgrades and Additions | Agile, Waterfall & Prince2 Project Management Templates | Microsoft Project Excel PowerPoint + RAID Log, POaP, Gantt View with Resource Cost Tracker etc.

FREE template upgrades for life available after purchase. This package contains ALL the PM templates offered by the seller,

The PM templates download link is contained in an ‘officedocdepot’ text file made available immediately after your purchase.

$ 89$ 120 -

OpEx – Apply Six Sigma to Process Control and Improvement

Channel: OpEx Academy NZSix Sigma for Process Control and Improvement

This document outlines a comprehensive Six Sigma training programme, focusing on process control and improvement using the DMAIC (Define, Measure, Analyse, Improve, Control) methodology. The material introduces Six Sigma as a framework for reducing variation and improving customer satisfaction through data-driven problem-solving, aiming for a performance level of 3.4 defects per million opportunities. It details each phase of DMAIC, providing specific tools and techniques, such as project charters, data collection plans, cause and effect diagrams, and control charts. The training incorporates practical simulations, like the “X Pult” exercise, to demonstrate the application of these methods in identifying problems, measuring performance, analysing root causes, implementing solutions, and sustaining improvements within an organisational context.$ 59$ 64 -

OpEx – Process Optimization using Six Sigma Techniques

Channel: OpEx Academy NZOptimizing Costs

This presentation, “OpEx – Optimise Cost,” by Vishnu Rayapeddi, outlines strategies for operational excellence focused on cost optimisation. It begins by explaining the importance of understanding customer needs and how they define quality, alongside methods for analysing cost and waste components. The document highlights various types of waste in manufacturing, such as defects, overproduction, and excessive motion, and offers practical exercises for identifying and reducing these costs. Furthermore, it introduces the concept of pull systems in production, contrasting them with traditional push systems to demonstrate their benefits in reducing operational costs and inventory. The presentation concludes by emphasising the importance of measuring results and implementing continuous improvement projects to achieve significant cost reductions and enhance customer satisfaction.$ 69$ 74 -

OpEx – Optimize Product Costs

Channel: OpEx Academy NZOptimizing Costs

This presentation, “OpEx – Optimise Cost,” by Vishnu Rayapeddi, outlines strategies for operational excellence focused on cost optimisation. It begins by explaining the importance of understanding customer needs and how they define quality, alongside methods for analysing cost and waste components. The document highlights various types of waste in manufacturing, such as defects, overproduction, and excessive motion, and offers practical exercises for identifying and reducing these costs. Furthermore, it introduces the concept of pull systems in production, contrasting them with traditional push systems to demonstrate their benefits in reducing operational costs and inventory. The presentation concludes by emphasising the importance of measuring results and implementing continuous improvement projects to achieve significant cost reductions and enhance customer satisfaction.$ 44$ 49 -

OpEx – LSS, Lean Six Sigma Memory Jogger

Channel: OpEx Academy NZThis document offers a ready refresher with over 50 LSS topics / fundamentals1(30

slides) on Lean Six Sigma and other related best practice concepts. It includes

tools, templates, and checklists. You can also use these as 1 Point Lessons

$ 49$ 54 -

OpEx – Business Integration Excellence Assessment

Channel: OpEx Academy NZUnderstand the current state of your business integration to set improvement goals

$ 29$ 34 -

OpEx – The Lean Supply Chain

Channel: OpEx Academy NZThe Lean Supply Chain

The source, “OpEx-Lean Supply Chain.pdf” by Vishnu Rayapeddi, outlines the concept of a lean supply chain as a crucial strategy for competitive advantage in the modern, complex global market. It details how Lean Thinking principles, such as customer focus, waste reduction, and continuous improvement, can be applied across all facets of a supply chain. The document explains various components of a lean supply chain, including lean suppliers, procurement, manufacturing, warehousing, and transportation, often referencing the SCOR model for identifying areas of waste. Ultimately, the text highlights the benefits of adopting a lean approach, such as increased speed, reduced inventories and costs, and improved customer satisfaction, and includes case studies like Tesco to illustrate its successful implementation.Transcript$ 39$ 44 -

OpEx – Kaizen, Continuous Improvement

Channel: OpEx Academy NZFacilitating Kaizen

The provided document, “OpEx-Facilitate CI-Kaizen.pdf” by Vishnu Rayapeddi, introduces Kaizen, a Japanese concept meaning gradual and orderly continuous improvement. It outlines a structured approach to fostering an organisational culture of sustained improvement by eliminating waste through various activities. The text highlights different types of Kaizen activities, including “Quick and Easy Kaizen” for daily small improvements and “Kaizen Events” (also known as “Kaizen Blitz”) for targeted, accelerated improvements. The Plan-Do-Check-Act (PDCA) cycle is presented as the core process for continuous improvement, emphasising the importance of standardising new processes to prevent regression. The document also details the planning, implementation, and follow-up phases for Kaizen events, suggesting a comprehensive framework for achieving operational excellence.$ 39$ 44 -

The Power and Magic of Lean by

Channel: OpEx Academy NZThe Power and Magic of Lean

The provided source offers an extensive overview of Lean principles and continuous improvement methodologies, largely attributed to the Toyota Production System (TPS). It introduces Norman Bodek, a prominent figure in propagating Japanese management techniques in the West, detailing his contributions and the various Lean tools he introduced, such as SMED, Poka-yoke, and Kaizen. The document meticulously outlines the nine wastes (Muda) that Lean aims to eliminate, including overproduction, waiting, and non-utilised talent, and explores concepts like Jidoka and Just-in-Time (JIT). Furthermore, it contrasts the characteristics of leaders and managers within a Lean context, emphasising the importance of respect for people and total employee involvement through practices like Quick and Easy Kaizen to foster a culture of perpetual small-scale improvements.$ 129$ 135

-

OpEx – PFEP, Plan For Every Part

Plan for Every Part

The provided document, “OpEx — PFEP – Plan For Every Part,” by Vishnu Rayapeddi, outlines a comprehensive strategy for optimising material handling and inventory management within an operational environment. It introduces the Plan For Every Part (PFEP) as a centralised database containing detailed information about every component, from purchasing to delivery. The text details a three-step implementation process: creating the initial PFEP database with current state information, developing a “plan” for each part based on this data, and establishing methods for sustaining and maintaining the database’s integrity, including the use of a change request form and a dedicated PFEP manager. The document also highlights the benefits of PFEP, such as enabling a lean material-handling system and providing quick responses to operational queries, while acknowledging that the PFEP itself is an “incidental” but crucial activity that supports value creation.$ 20$ 25OpEx – PFEP, Plan For Every Part

$ 20$ 25